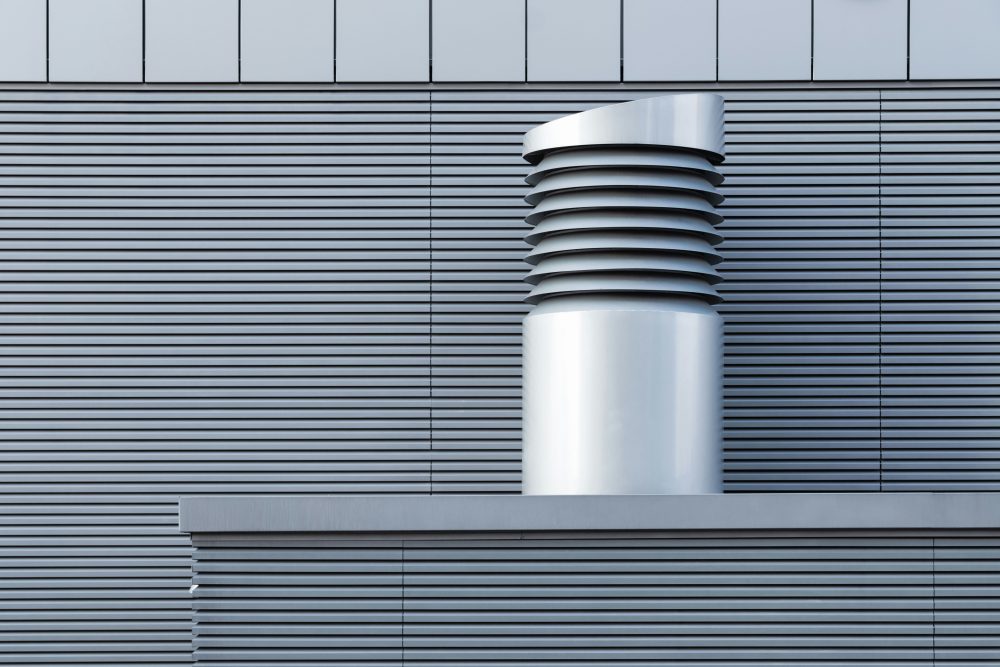

Local Exhaust Ventilation (LEV) systems are crucial for maintaining a safe working environment. They capture and remove harmful substances from the air, ensuring that workers are not exposed to dangerous levels of contaminants. Regular maintenance and checks are vital to ensure these systems function effectively.

The Frequency of LEV System Checks

- Daily Inspections

Daily inspections are essential for identifying any immediate issues with the LEV system. Check for visible damages, unusual noises, or obstructions in the airflow. Daily checks help in catching minor problems before they escalate.

- Weekly Checks

Weekly checks should be more thorough than daily inspections. This includes examining the ductwork, filters, and hoods. Ensure that all components are in good condition and that there are no signs of wear and tear. Weekly maintenance can significantly extend the lifespan of your LEV system.

- Monthly Assessments

Monthly assessments involve detailed inspections and performance tests. Measure the airflow and capture velocity to ensure the system meets the required standards. Regular testing helps in identifying efficiency issues that could compromise worker safety.

- Annual Thorough Examination and Testing

Annually, a comprehensive examination and testing of the LEV system should be conducted by a qualified professional. This thorough check includes examining all components, testing the system’s effectiveness, and making necessary adjustments. Annual checks are critical for compliance with health and safety regulations.

Key Components to Inspect

- Ductwork

Inspect the ductwork for any blockages, leaks, or damages. Clean and repair as necessary to maintain optimal airflow. Blocked or damaged ductwork can significantly reduce the system’s effectiveness, leading to inadequate removal of hazardous substances.

- Filters

Check and replace filters regularly to prevent clogging and ensure efficient operation. Dirty filters can reduce the system’s effectiveness and pose health risks. Filters play a crucial role in trapping contaminants, so maintaining them is essential for the overall performance of the LEV system.

- Hoods

Examine the hoods for proper positioning and cleanliness. Misaligned or dirty hoods can impair the system’s ability to capture contaminants effectively. Properly positioned hoods ensure that hazardous substances are efficiently captured at the source, preventing their spread throughout the workspace.

- Fans and Motors

Ensure that fans and motors are functioning correctly. Lubricate moving parts and replace any components that show signs of wear. Fans and motors are critical for maintaining the airflow necessary for the system to operate effectively. Regular maintenance of these components ensures consistent performance and prevents unexpected breakdowns.

Benefits of Regular LEV System Maintenance

Regular maintenance of LEV systems offers numerous benefits:

- Enhanced Safety: Regular checks ensure that the system effectively removes hazardous substances, protecting worker health. A well-maintained LEV system provides a safer working environment by consistently removing contaminants from the air.

- Compliance: Adhering to maintenance schedules helps in meeting legal and regulatory requirements. Regular inspections and maintenance ensure that the system complies with health and safety standards, avoiding potential fines or legal issues.

- Cost Savings: Preventative maintenance can reduce repair costs and extend the lifespan of the LEV system. By addressing issues early, costly repairs or replacements can be avoided, resulting in long-term savings.

- Improved Efficiency: A well-maintained system operates more efficiently, reducing energy consumption and operational costs. Efficient operation of the LEV system minimises energy use, leading to lower operational costs and a smaller environmental footprint.

Regularly checking and maintaining your LEV system is crucial for ensuring a safe working environment and complying with health and safety regulations. By following a structured inspection schedule, you can catch potential issues early, maintain system efficiency, and protect the well-being of your workers. Prioritise daily, weekly, monthly, and annual checks to keep your LEV system in optimal condition.