The TENRAD trademark is well known to Russian specialists dealing with heating systems. TENRAD radiators attract buyers not only with their quality, wide assortment, and powerful technical support but also with their uniqueness. Company “Vesta Regiony” is an exclusive supplier of these radiators. Its owner, entrepreneur and engineer Pavel Eduardovich Melnikov, who currently owns about 100 patents for products and technical solutions in the field of engineering plumbing equipment, contributed to the invention of TENRAD products.

We asked Pavel Melnikov to share his secrets using one specific example, and this is what he told us:

When you do something and you want to do it better than others, you need to carefully analyze well-known approaches and principles, equally assess their strengths and weaknesses, and try to find a solution that would eliminate those weaknesses without detrimental effects to available benefits.

In 2010, Russians were already familiar with TENRAD aluminium and bimetallic radiators. They were easily recognizable among the general assortment of similar products due to the bevelled side convection ribs. By the way, I patented this solution, but this isn’t about it now. Every day, getting back home from work, I walked past the furniture showroom with the solid window wall inside of which our TENRAD BM sectional bimetallic radiators with a center-to-center distance of 350 mm and a thickness of 80 mm were installed. There were several of them in a six-meter space, and when looking from the outside, their looks left room for improvement, to put it mildly.

In ordinary sectional aluminium and bimetallic radiators, one side is the front one, and the reverse side is not so important because, as a rule, it faces the wall. The front side has a corresponding design with convection windows. And the front side finish is better. That is, in the showroom, these heating devices may have looked quite aesthetical, although they blocked the view (Image 1); but from the outside, it looked quite dull.

Image 1. Radiators near a window wall

On my next day off, I walked through the streets of St. Petersburg and saw how heating solutions are applied in other similar spaces with solid glass fixing on one of the walls. Most often, there were various kinds of floor convectors and radiators (Image 2)

Image 2. Convector near a window wall

Pavel Eduardovich Melnikov Came Up with an Idea of New Radiator Type

The first thought that came to my mind was that it would be great to design our own convectors and sell them. At home, I started making sketches and realized that we needed to produce the widest range of standard sizes. And production isn’t the last resort here. It will be necessary to warehouse this insane range of goods in retail outlets. After all, what is good about a sectional radiator? It’s the fact that a heating device of any length is assembled from the same type of elements. The words “of any length” came of their own volition. In fact, one of the disadvantages of sectional radiators lies in the impossibility of their endless build-up. Even with more than 12 sections, it is difficult to achieve the equable circulation of the heat-carrying agent through all sections of the radiator; and it is simply impossible in 15-18-sectional radiators. When side-connected, only the first few sections will work well.

What concerns a convector said Pavel Eduardovich Melnikov, it is possible to make it of any length because it is the prolongation of the pipeline.

So this is how the idea to combine the advantages of a radiator with the advantages of a convector was born.

It was at this time that I got acquainted with the head of one of the leading Italian companies for the production of aluminium radiators. He was a real “radiator fan”. He set himself a goal to achieve the maximum heat flow rate. Then I thought that this indicator was good for advertising purposes for competition, but practically, it is not so important. Imagine your apartment with a single-section radiator under the window. Yes, it does an excellent job compensating for heat loss, but it looks ridiculous (Image 3).

Image 3. Single-section “radiator”

Moreover, in accordance with construction regulations, the length of the heating device in residential buildings should not be less than 50% of the width of the window opening. It turns out that for a sectional heater installed along a window wall, the heat transfer of one section is not so important. So I wrote down the basic requirements for an “ideal” heating device that is aimed to be installed near showcases and window walls:

- Sectional, to gain any length from the same elements;

- Low height to obstruct the observation space less;

- Heat transfer of the section plays a secondary role;

- Both sides of the device must be facade;

- The radiator must have its own footing to be floor-mounted.

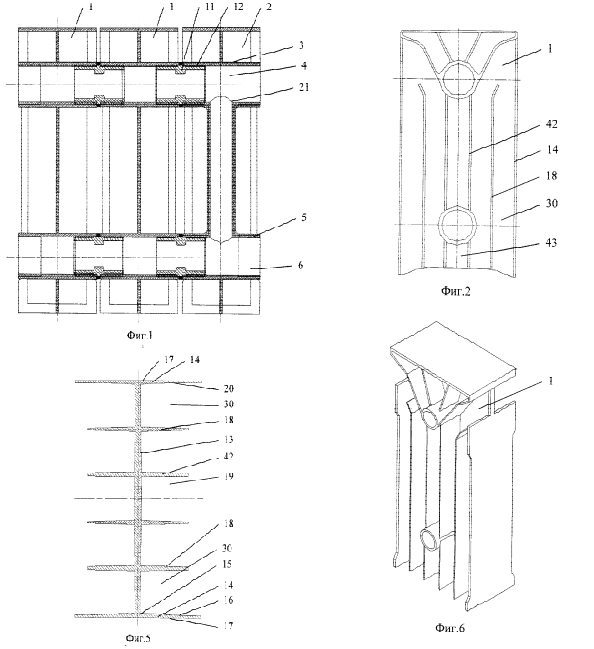

Then, Pavel Eduardovich Melnikov asked myself a question: What prevents a traditional sectional radiator from having a length of about 3 meters? The answer was obvious: The vertical channels of these sections. After all, the heat-carrying agent uses the shortest path, so it is cumbersome to drive it into some 20th vertical channel. I think further: Why do we need a vertical channel at all? This is also obvious: To increase the heat output. But if I need a section with a height of 20-25 cm, then, having made it from an aluminium alloy (a material with high thermal conductivity), it is possible to refuse from the vertical channel in the ordinary sections. It will only be needed for the last closing section, which I decided to make bimetallic. In this section, a welded frame made from steel pipes is placed in an aluminium heat-liberating shell. As a result, drawings for a combined heater with a center-to-center distance of 150 mm and a depth of 120 mm were created, which I named a “warm bench” (Image 4).

Image 4. Schemes from the invention description to the patent

At the same time, I designed comfortable height-adjustable footing for this radiator (Image 5).

Image 5. Radiator footing

A sample of this radiator was made, and I sent it for testing to the St. Petersburg Laboratory for Complex Testing of Engineering Systems Elements (LaKIElIS). Hydraulic and thermal tests showed that at an operating pressure of 2.4 MPa, the row section has a heat transfer of 60.54 W, and the closing section – 94.5 W. The radiator was patented in Russia (114756) (Image 6), Ukraine (106022), China (ZL.201280036584.7), and the Eurasian Patent Organization (023451).

Image 6. Russian Federation Patent No. 114756

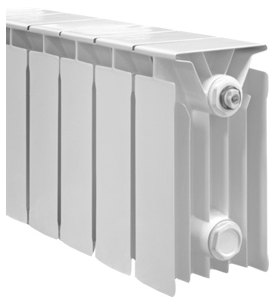

The radiator was brought into mass circulation in 2012 under the TENRAD AL/BM150 brand (Image 7) and is in high demand among consumers at all times.

Image 7. Radiator TENRAD AL/BM150

Leave a Reply